DEMO_febio_00014_cube_varying_material

Below is a demonstration for:

- Building geometry for a cube with hexahedral elements

- Defining the boundary conditions

- Coding the febio structure

- Running the model

- Importing and visualizing the displacement and stress results

Contents

- Keywords

- Plot settings

- Control parameters

- Creating model geometry and mesh

- Define spatially varying material distribution data

- Defining the boundary conditions

- Defining the FEBio input structure

- Quick viewing of the FEBio input file structure

- Exporting the FEBio input file

- Running the FEBio analysis

- Import FEBio results

Keywords

- febio_spec version 4.0

- febio, FEBio

- compression, tension, compressive, tensile

- displacement control, displacement boundary condition

- hexahedral elements, hex8

- cube, box, rectangular

- static, solid

- spatially varying material properties

- hyperelastic, Ogden

- displacement logfile

- stress logfile

clear; close all; clc;

Plot settings

fontSize=15; faceAlpha1=0.8; markerSize=40; lineWidth=3; cMap=spectral(250);

Control parameters

% Path names defaultFolder = fileparts(fileparts(mfilename('fullpath'))); savePath=fullfile(defaultFolder,'data','temp'); % Defining file names febioFebFileNamePart='tempModel'; febioFebFileName=fullfile(savePath,[febioFebFileNamePart,'.feb']); %FEB file name febioLogFileName=[febioFebFileNamePart,'.txt']; %FEBio log file name febioLogFileName_disp=[febioFebFileNamePart,'_disp_out.txt']; %Log file name for exporting force febioLogFileName_sed=[febioFebFileNamePart,'_sed_out.txt']; %Log file name for exporting strain energy density %Specifying dimensions and number of elements pointSpacings=1*ones(1,3); %Desired point spacing between nodes cubeSize=10; sampleWidth=cubeSize; %Width sampleThickness=cubeSize; %Thickness sampleHeight=cubeSize; %Height numElementsWidth=round(sampleWidth/pointSpacings(1)); %Number of elemens in dir 1 numElementsThickness=round(sampleThickness/pointSpacings(2)); %Number of elemens in dir 2 numElementsHeight=round(sampleHeight/pointSpacings(3)); %Number of elemens in dir 3 %Define applied displacement appliedStrain=0.3; %Linear strain (Only used to compute applied stretch) loadingOption='tension'; % or 'compression' switch loadingOption case 'compression' stretchLoad=1-appliedStrain; %The applied stretch for uniaxial loading case 'tension' stretchLoad=1+appliedStrain; %The applied stretch for uniaxial loading end displacementMagnitude=(stretchLoad*sampleHeight)-sampleHeight; %The displacement magnitude %Material parameter sets testOpt=2; %1=Linear gradient of material, or 2=gyroid based material distribution E_youngs_min=1e-3; %Lowest Youngs modulus E_youngs_max=1; %Highest Youngs modulus nu_min=0.3; %Lowest Poissons ratio nu_max=0.45; %Lowest Poissons ratio % FEA control settings numTimeSteps=10; %Number of time steps desired max_refs=25; %Max reforms max_ups=0; %Set to zero to use full-Newton iterations opt_iter=6; %Optimum number of iterations max_retries=5; %Maximum number of retires dtmin=(1/numTimeSteps)/100; %Minimum time step size dtmax=1/numTimeSteps; %Maximum time step size runMode='external'; % 'internal' or 'external'

Creating model geometry and mesh

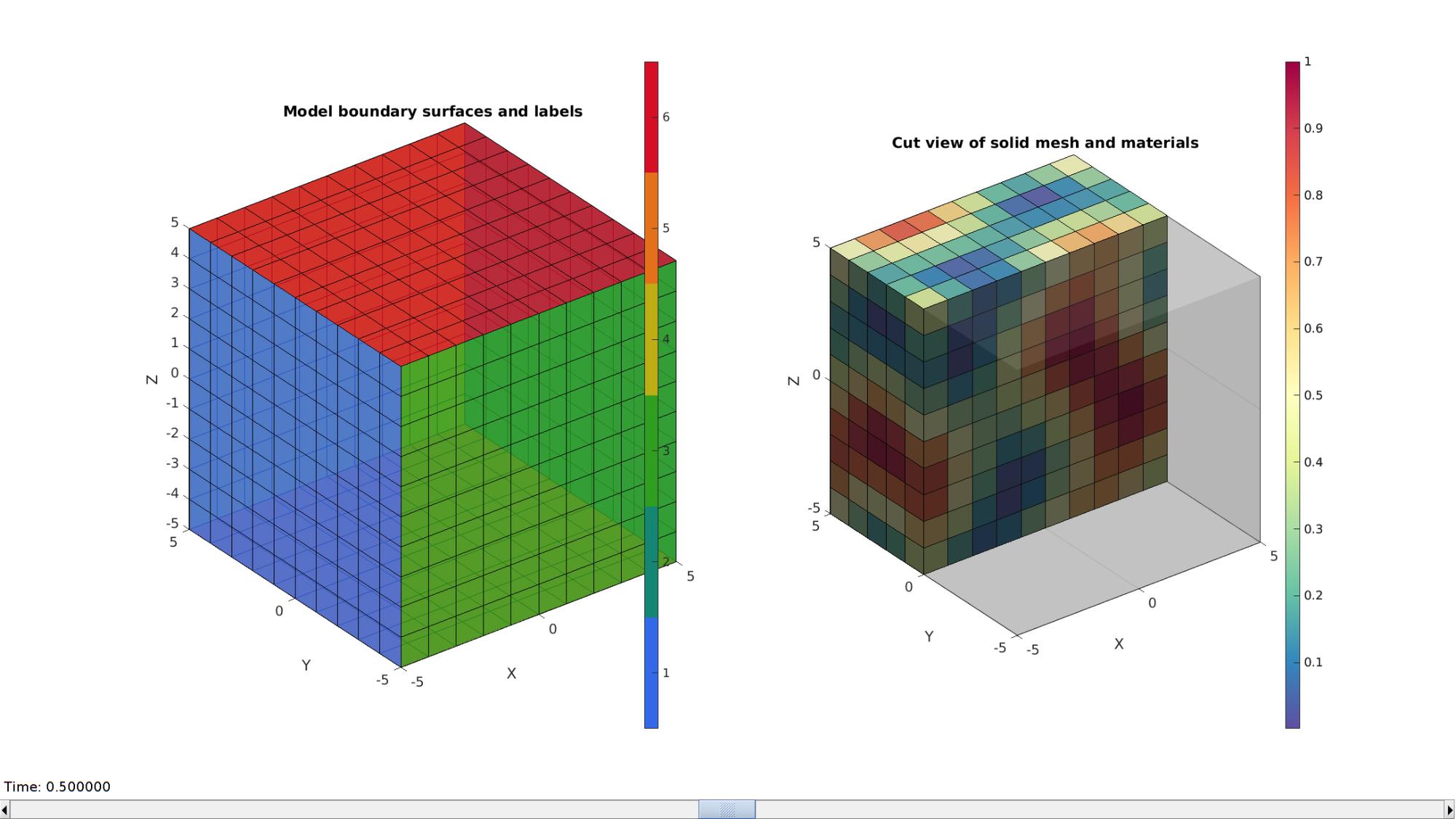

A box is created with tri-linear hexahedral (hex8) elements using the hexMeshBox function. The function offers the boundary faces with seperate labels for the top, bottom, left, right, front, and back sides. As such these can be used to define boundary conditions on the exterior.

% Create a box with hexahedral elements cubeDimensions=[sampleWidth sampleThickness sampleHeight]; %Dimensions cubeElementNumbers=[numElementsWidth numElementsThickness numElementsHeight]; %Number of elements outputStructType=2; %A structure compatible with mesh view [meshStruct]=hexMeshBox(cubeDimensions,cubeElementNumbers,outputStructType); %Access elements, nodes, and faces from the structure E=meshStruct.elements; %The elements V=meshStruct.nodes; %The nodes (vertices) Fb=meshStruct.facesBoundary; %The boundary faces Cb=meshStruct.boundaryMarker; %The "colors" or labels for the boundary faces

Define spatially varying material distribution data

Here the element centre coordinates are used assign the material stiffness based on a particular function on these coordinates.

VE=patchCentre(E,V); %Element centres switch testOpt case 1 %linear gradient in X direction S=VE(:,1); case 2 %gyroid %Scale coordinates for gyroid VE=VE-min(VE(:)); VE=VE./max(VE(:)); VE=(VE.*2*pi)-pi; %Evaluate gyroid S=triplyPeriodicMinimal(VE(:,1),VE(:,2),VE(:,3),'g'); end %Normalize data S=S-min(S(:)); %Subtract minimum -> range [0-...] S=S./max(S(:)); %Devide by max -> range [0-1] %Use scaling data S to generate element Youngs moduli E_youngs_elem=S.*(E_youngs_max-E_youngs_min)+E_youngs_min; nu_elem=S.*(nu_max-nu_min)+nu_min; %Fix mesh struct for plotting meshStruct.elements=E; meshStruct.elementData=E_youngs_elem;

Plotting model boundary surfaces and a cut view

hFig=cFigure; subplot(1,2,1); hold on; title('Model boundary surfaces and labels','FontSize',fontSize); gpatch(Fb,V,Cb,'k',faceAlpha1); colormap(gca,gjet(6)); icolorbar; axisGeom(gca,fontSize); hs=subplot(1,2,2); hold on; title('Cut view of solid mesh and materials','FontSize',fontSize); optionStruct.hFig=[hFig hs]; meshView(meshStruct,optionStruct); colormap(gca,cMap); colorbar; caxis([E_youngs_min E_youngs_max]); axisGeom(gca,fontSize); drawnow;

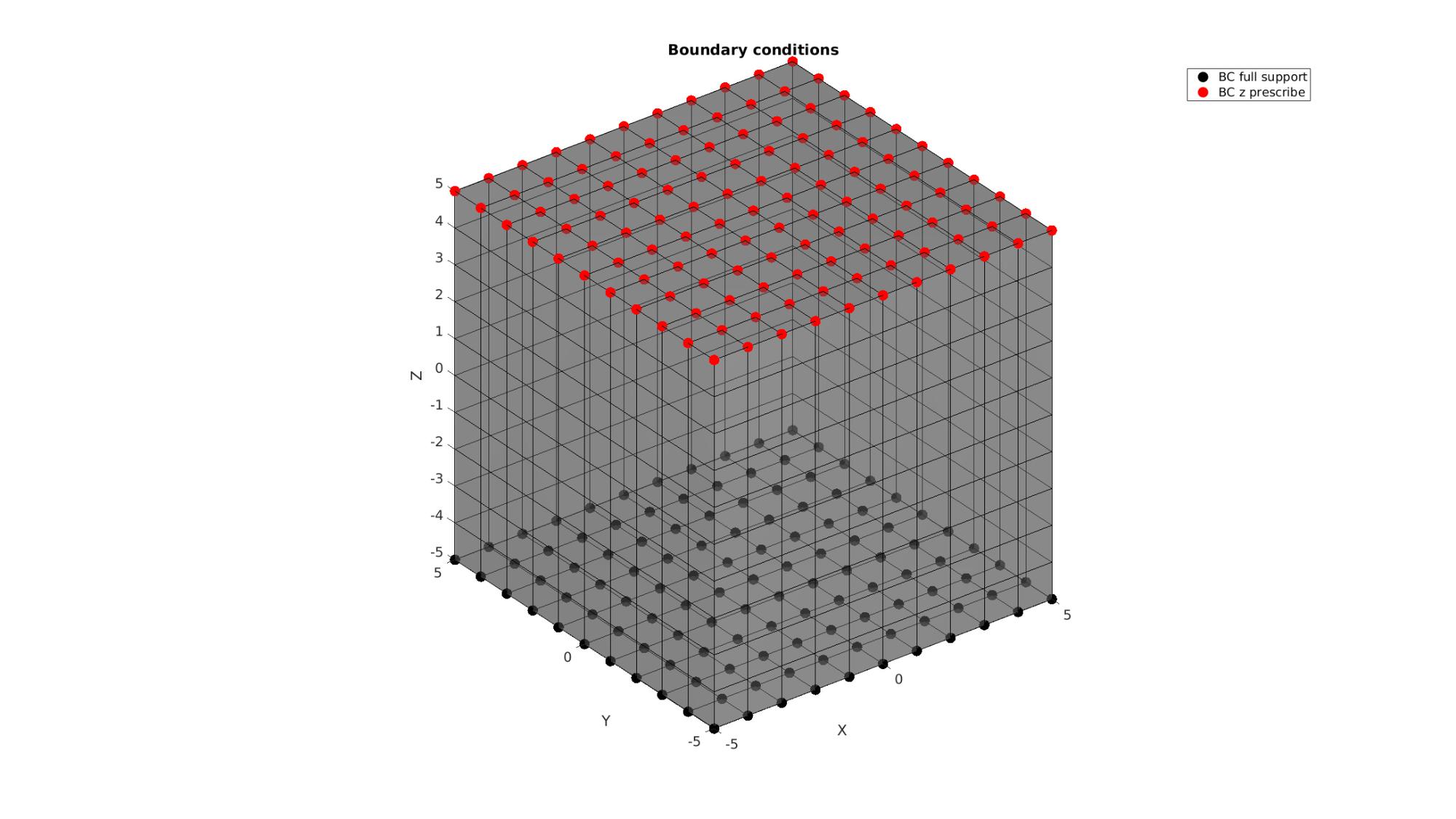

Defining the boundary conditions

The visualization of the model boundary shows colors for each side of the cube. These labels can be used to define boundary conditions.

%Define supported node sets bcSupportList=unique(Fb(Cb==5,:)); %Node set part of selected face %Prescribed displacement nodes bcPrescribeList=unique(Fb(Cb==6,:)); %Node set part of selected face

Visualizing boundary conditions. Markers plotted on the semi-transparent model denote the nodes in the various boundary condition lists.

hf=cFigure; title('Boundary conditions','FontSize',fontSize); xlabel('X','FontSize',fontSize); ylabel('Y','FontSize',fontSize); zlabel('Z','FontSize',fontSize); hold on; gpatch(Fb,V,'kw','k',0.5); hl(1)=plotV(V(bcSupportList,:),'k.','MarkerSize',markerSize); hl(2)=plotV(V(bcPrescribeList,:),'r.','MarkerSize',markerSize); legend(hl,{'BC full support','BC z prescribe'}); axisGeom(gca,fontSize); camlight headlight; drawnow;

Defining the FEBio input structure

See also febioStructTemplate and febioStruct2xml and the FEBio user manual.

%Get a template with default settings [febio_spec]=febioStructTemplate; %febio_spec version febio_spec.ATTR.version='4.0'; %Module section febio_spec.Module.ATTR.type='solid'; %Control section febio_spec.Control.analysis='STATIC'; febio_spec.Control.time_steps=numTimeSteps; febio_spec.Control.step_size=1/numTimeSteps; febio_spec.Control.solver.max_refs=max_refs; febio_spec.Control.time_stepper.dtmin=dtmin; febio_spec.Control.time_stepper.dtmax=dtmax; febio_spec.Control.time_stepper.max_retries=max_retries; febio_spec.Control.time_stepper.opt_iter=opt_iter; %Material section materialName1='Material1'; dataMapName1='MaterialParameterMap1'; dataMapName2='MaterialParameterMap2'; febio_spec.Material.material{1}.ATTR.name=materialName1; febio_spec.Material.material{1}.ATTR.type='neo-Hookean'; febio_spec.Material.material{1}.ATTR.id=1; febio_spec.Material.material{1}.E.ATTR.type='map'; %Calls for mapping of parameter febio_spec.Material.material{1}.E.VAL=dataMapName1; %Calls for mapping of parameter febio_spec.Material.material{1}.v.ATTR.type='map'; %Calls for mapping of parameter febio_spec.Material.material{1}.v.VAL=dataMapName2; %Calls for mapping of parameter % Mesh section % -> Nodes febio_spec.Mesh.Nodes{1}.ATTR.name='Object1'; %The node set name febio_spec.Mesh.Nodes{1}.node.ATTR.id=(1:size(V,1))'; %The node id's febio_spec.Mesh.Nodes{1}.node.VAL=V; %The nodel coordinates % -> Elements partName1='Part1'; febio_spec.Mesh.Elements{1}.ATTR.name=partName1; %Name of this part febio_spec.Mesh.Elements{1}.ATTR.type='hex8'; %Element type febio_spec.Mesh.Elements{1}.elem.ATTR.id=(1:1:size(E,1))'; %Element id's febio_spec.Mesh.Elements{1}.elem.VAL=E; %The element matrix % -> NodeSets nodeSetName1='bcSupportList'; nodeSetName2='bcPrescribeList'; febio_spec.Mesh.NodeSet{1}.ATTR.name=nodeSetName1; febio_spec.Mesh.NodeSet{1}.VAL=mrow(bcSupportList); febio_spec.Mesh.NodeSet{2}.ATTR.name=nodeSetName2; febio_spec.Mesh.NodeSet{2}.VAL=mrow(bcPrescribeList); %MeshData secion %-> Element data febio_spec.MeshData.ElementData{1}.ATTR.name=dataMapName1; febio_spec.MeshData.ElementData{1}.ATTR.elem_set=partName1; febio_spec.MeshData.ElementData{1}.elem.ATTR.lid=(1:1:size(E,1))'; febio_spec.MeshData.ElementData{1}.elem.VAL=E_youngs_elem; febio_spec.MeshData.ElementData{2}.ATTR.name=dataMapName2; febio_spec.MeshData.ElementData{2}.ATTR.elem_set=partName1; febio_spec.MeshData.ElementData{2}.elem.ATTR.lid=(1:1:size(E,1))'; febio_spec.MeshData.ElementData{2}.elem.VAL=nu_elem; %MeshDomains section febio_spec.MeshDomains.SolidDomain.ATTR.name=partName1; febio_spec.MeshDomains.SolidDomain.ATTR.mat=materialName1; %Boundary condition section % -> Fix boundary conditions febio_spec.Boundary.bc{1}.ATTR.name='FixedDisplacement01'; febio_spec.Boundary.bc{1}.ATTR.type='zero displacement'; febio_spec.Boundary.bc{1}.ATTR.node_set=nodeSetName1; febio_spec.Boundary.bc{1}.x_dof=1; febio_spec.Boundary.bc{1}.y_dof=1; febio_spec.Boundary.bc{1}.z_dof=1; febio_spec.Boundary.bc{2}.ATTR.name='FixedDisplacement02'; febio_spec.Boundary.bc{2}.ATTR.type='zero displacement'; febio_spec.Boundary.bc{2}.ATTR.node_set=nodeSetName2; febio_spec.Boundary.bc{2}.x_dof=1; febio_spec.Boundary.bc{2}.y_dof=1; febio_spec.Boundary.bc{2}.z_dof=0; febio_spec.Boundary.bc{3}.ATTR.name='bcPrescribeList'; febio_spec.Boundary.bc{3}.ATTR.type='prescribed displacement'; febio_spec.Boundary.bc{3}.ATTR.node_set=nodeSetName2; febio_spec.Boundary.bc{3}.dof='z'; febio_spec.Boundary.bc{3}.value.ATTR.lc=1; febio_spec.Boundary.bc{3}.value.VAL=displacementMagnitude; febio_spec.Boundary.bc{3}.relative=0; %LoadData section % -> load_controller febio_spec.LoadData.load_controller{1}.ATTR.name='LC1'; febio_spec.LoadData.load_controller{1}.ATTR.id=1; febio_spec.LoadData.load_controller{1}.ATTR.type='loadcurve'; febio_spec.LoadData.load_controller{1}.interpolate='LINEAR'; febio_spec.LoadData.load_controller{1}.extend='CONSTANT'; febio_spec.LoadData.load_controller{1}.points.pt.VAL=[0 0; 1 1]; %Output section % -> log file febio_spec.Output.logfile.ATTR.file=febioLogFileName; febio_spec.Output.logfile.node_data{1}.ATTR.file=febioLogFileName_disp; febio_spec.Output.logfile.node_data{1}.ATTR.data='ux;uy;uz'; febio_spec.Output.logfile.node_data{1}.ATTR.delim=','; febio_spec.Output.logfile.element_data{1}.ATTR.file=febioLogFileName_sed; febio_spec.Output.logfile.element_data{1}.ATTR.data='sed'; febio_spec.Output.logfile.element_data{1}.ATTR.delim=','; febio_spec.Output.plotfile.compression=0;

Quick viewing of the FEBio input file structure

The febView function can be used to view the xml structure in a MATLAB figure window.

febView(febio_spec); %Viewing the febio file

Exporting the FEBio input file

Exporting the febio_spec structure to an FEBio input file is done using the febioStruct2xml function.

febioStruct2xml(febio_spec,febioFebFileName); %Exporting to file and domNode % febView(febioFebFileName);

Running the FEBio analysis

To run the analysis defined by the created FEBio input file the runMonitorFEBio function is used. The input for this function is a structure defining job settings e.g. the FEBio input file name. The optional output runFlag informs the user if the analysis was run succesfully.

febioAnalysis.run_filename=febioFebFileName; %The input file name febioAnalysis.run_logname=febioLogFileName; %The name for the log file febioAnalysis.disp_on=1; %Display information on the command window febioAnalysis.runMode=runMode; [runFlag]=runMonitorFEBio(febioAnalysis);%START FEBio NOW!!!!!!!!

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

--------> RUNNING/MONITORING FEBIO JOB <-------- 20-Apr-2023 10:41:38

FEBio path: /home/kevin/FEBioStudio2/bin/febio4

# Attempt removal of existing log files 20-Apr-2023 10:41:38

* Removal succesful 20-Apr-2023 10:41:38

# Attempt removal of existing .xplt files 20-Apr-2023 10:41:38

* Removal succesful 20-Apr-2023 10:41:38

# Starting FEBio... 20-Apr-2023 10:41:38

Max. total analysis time is: Inf s

* Waiting for log file creation 20-Apr-2023 10:41:38

Max. wait time: 30 s

* Log file found. 20-Apr-2023 10:41:38

# Parsing log file... 20-Apr-2023 10:41:38

number of iterations : 3 20-Apr-2023 10:41:38

number of reformations : 3 20-Apr-2023 10:41:38

------- converged at time : 0.1 20-Apr-2023 10:41:38

number of iterations : 3 20-Apr-2023 10:41:38

number of reformations : 3 20-Apr-2023 10:41:38

------- converged at time : 0.2 20-Apr-2023 10:41:38

number of iterations : 3 20-Apr-2023 10:41:39

number of reformations : 3 20-Apr-2023 10:41:39

------- converged at time : 0.3 20-Apr-2023 10:41:39

number of iterations : 3 20-Apr-2023 10:41:39

number of reformations : 3 20-Apr-2023 10:41:39

------- converged at time : 0.4 20-Apr-2023 10:41:39

number of iterations : 3 20-Apr-2023 10:41:39

number of reformations : 3 20-Apr-2023 10:41:39

------- converged at time : 0.5 20-Apr-2023 10:41:39

number of iterations : 3 20-Apr-2023 10:41:39

number of reformations : 3 20-Apr-2023 10:41:39

------- converged at time : 0.6 20-Apr-2023 10:41:39

number of iterations : 3 20-Apr-2023 10:41:40

number of reformations : 3 20-Apr-2023 10:41:40

------- converged at time : 0.7 20-Apr-2023 10:41:40

number of iterations : 3 20-Apr-2023 10:41:40

number of reformations : 3 20-Apr-2023 10:41:40

------- converged at time : 0.8 20-Apr-2023 10:41:40

number of iterations : 3 20-Apr-2023 10:41:40

number of reformations : 3 20-Apr-2023 10:41:40

------- converged at time : 0.9 20-Apr-2023 10:41:40

number of iterations : 3 20-Apr-2023 10:41:40

number of reformations : 3 20-Apr-2023 10:41:40

------- converged at time : 1 20-Apr-2023 10:41:40

Elapsed time : 0:00:01 20-Apr-2023 10:41:40

N O R M A L T E R M I N A T I O N

# Done 20-Apr-2023 10:41:40

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

Import FEBio results

if runFlag==1 %i.e. a succesful run

Importing nodal displacements from a log file

dataStruct=importFEBio_logfile(fullfile(savePath,febioLogFileName_disp),0,1);

%Access data

N_disp_mat=dataStruct.data; %Displacement

timeVec=dataStruct.time; %Time

%Create deformed coordinate set

V_DEF=N_disp_mat+repmat(V,[1 1 size(N_disp_mat,3)]);

Importing element stress from a log file

dataStruct=importFEBio_logfile(fullfile(savePath,febioLogFileName_sed),0,1);

%Access data

E_sed_mat=dataStruct.data;

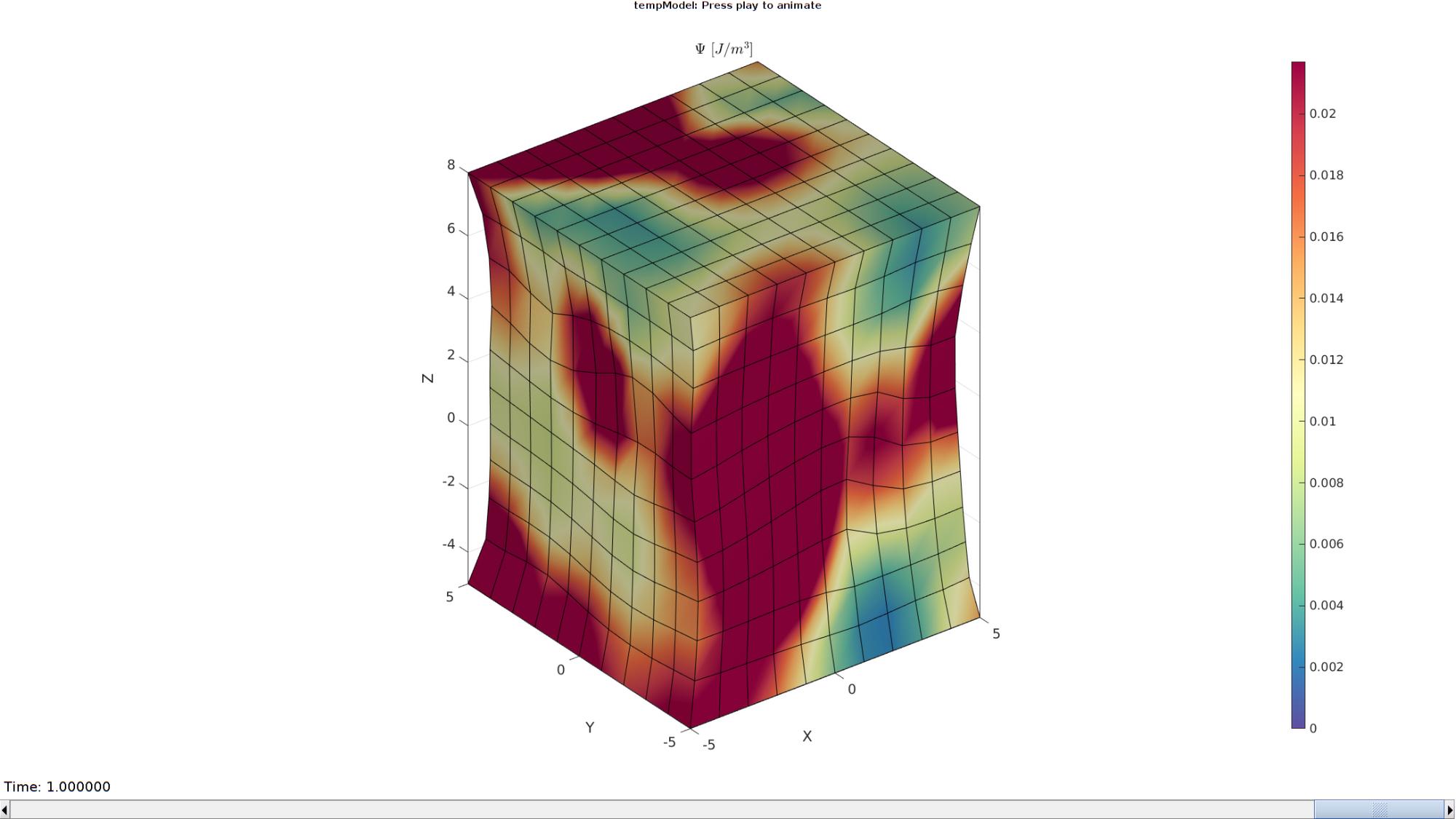

Plotting the simulated results using anim8 to visualize and animate deformations

[CV]=faceToVertexMeasure(E,V,E_sed_mat(:,:,end));

% Create basic view and store graphics handle to initiate animation

hf=cFigure; %Open figure

gtitle([febioFebFileNamePart,': Press play to animate']);

title('$\Psi$ $[J/m^3]$','Interpreter','Latex')

hp=gpatch(Fb,V_DEF(:,:,end),CV,'k',1); %Add graphics object to animate

hp.FaceColor='interp';

axisGeom(gca,fontSize);

colormap(cMap); colorbar;

caxis([min(E_sed_mat(:)) max(E_sed_mat(:))]/3);

axis(axisLim(V_DEF)); %Set axis limits statically

camlight headlight;

% Set up animation features

animStruct.Time=timeVec; %The time vector

for qt=1:1:size(N_disp_mat,3) %Loop over time increments

[CV]=faceToVertexMeasure(E,V,E_sed_mat(:,:,qt));

%Set entries in animation structure

animStruct.Handles{qt}=[hp hp]; %Handles of objects to animate

animStruct.Props{qt}={'Vertices','CData'}; %Properties of objects to animate

animStruct.Set{qt}={V_DEF(:,:,qt),CV}; %Property values for to set in order to animate

end

anim8(hf,animStruct); %Initiate animation feature

drawnow;

end

GIBBON www.gibboncode.org

Kevin Mattheus Moerman, [email protected]

GIBBON footer text

License: https://github.com/gibbonCode/GIBBON/blob/master/LICENSE

GIBBON: The Geometry and Image-based Bioengineering add-On. A toolbox for image segmentation, image-based modeling, meshing, and finite element analysis.

Copyright (C) 2006-2022 Kevin Mattheus Moerman and the GIBBON contributors

This program is free software: you can redistribute it and/or modify it under the terms of the GNU General Public License as published by the Free Software Foundation, either version 3 of the License, or (at your option) any later version.

This program is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; without even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU General Public License for more details.

You should have received a copy of the GNU General Public License along with this program. If not, see http://www.gnu.org/licenses/.