DEMO_febio_0071_pneunet_actuator_set_01

Below is a demonstration for:

- Building geometry for a simple pneunet actuator

- Defining the boundary conditions

- Coding the febio structure

- Running the model

- Importing and visualizing the displacement and stress results

Contents

- Keywords

- Plot settings

- Control parameters

- Removed unused nodes and clean up index matrices

- Defining the boundary conditions

- Split element regions (central plate and sides);

- Defining the FEBio input structure

- Quick viewing of the FEBio input file structure

- Exporting the FEBio input file

- Running the FEBio analysis

- Import FEBio results

Keywords

- febio_spec version 4.0

- febio, FEBio

- pressure loading

- hexahedral elements, hex8

- pneunet actuator

- soft robotic

- static, solid

- hyperelastic, Ogden

- displacement logfile

- stress logfile

clear; close all; clc;

Plot settings

fontSize=20; faceAlpha1=0.8; markerSize=40; markerSize2=20; lineWidth=3;

Control parameters

% Path names defaultFolder = fileparts(fileparts(mfilename('fullpath'))); savePath=fullfile(defaultFolder,'data','temp'); % Defining file names febioFebFileNamePart='tempModel'; febioFebFileName=fullfile(savePath,[febioFebFileNamePart,'.feb']); %FEB file name febioLogFileName=fullfile(savePath,[febioFebFileNamePart,'.txt']); %FEBio log file name febioLogFileName_disp=[febioFebFileNamePart,'_disp_out.txt']; %Log file name for exporting displacement febioLogFileName_stress=[febioFebFileNamePart,'_stress_out.txt']; %Log file name for exporting force %Load appliedPressure1=0.05; appliedPressure2=appliedPressure1/10; %Define applied force appliedForce=[1e-12 0 0]; %Material parameter set c1=1; %Shear-modulus-like parameter m1=2; %Material parameter setting degree of non-linearity k_factor=50; %Bulk modulus factor k=c1*k_factor; %Bulk modulus c2=50*c1; %Shear-modulus-like parameter m2=2; %Material parameter setting degree of non-linearity k2=c2*k_factor; %Bulk modulus % FEA control settings numTimeSteps=10; %Number of time steps desired opt_iter=25; %Optimum number of iterations max_refs=opt_iter*2; %Max reforms max_ups=0; %Set to zero to use full-Newton iterations max_retries=5; %Maximum number of retires dtmin=(1/numTimeSteps)/100; %Minimum time step size dtmax=(1/numTimeSteps); %Maximum time step size runMode='external';%'internal';

actuatorLengthDesired=100; pointSpacing=2; periodSize=10; numPeriods=ceil(actuatorLengthDesired/periodSize); heightFactor=1.4; %To scale height wrt period size widthFactor=1; %To scale width wrt period size numElementsPeriod=ceil(periodSize./pointSpacing); if numElementsPeriod<4 numElementsPeriod=4; end numElementsLength=((numPeriods-1)*numElementsPeriod)+(numElementsPeriod-1); modelLength=numElementsLength.*pointSpacing; modelHeight_X=periodSize*heightFactor; modelWidth_Y=periodSize*widthFactor; numElementsHeight_X=ceil(modelHeight_X./pointSpacing); if numElementsHeight_X<6 numElementsHeight_X=6; end numElementsWidth_Y=ceil(modelWidth_Y./pointSpacing); if numElementsWidth_Y<1 numElementsWidth_Y=1; end boxDim=[modelHeight_X modelWidth_Y modelLength]; boxEl=[numElementsHeight_X numElementsWidth_Y numElementsLength]; [meshStruct]=hexMeshBox(boxDim,boxEl); E_bar=meshStruct.E; V_bar=meshStruct.V; F_bar=meshStruct.F; Fb_bar=meshStruct.Fb; Cb_bar=meshStruct.faceBoundaryMarker; VE_bar=patchCentre(E_bar,V_bar); CZ=VE_bar(:,3); CZ=CZ-min(CZ); CZ=CZ./max(CZ); CZ=round((CZ.*(numElementsLength-1)))+1; CW=VE_bar(:,1); CW=CW-min(CW); CW=CW./max(CW); CW=round((CW.*(numElementsHeight_X-1)))+1; CD=rem(CZ,numElementsPeriod); logicKeep1=~(CD==0 & CW>3); E1=E_bar(logicKeep1,:); F1=element2patch(E1); [indBoundary1]=tesBoundary(F1); logicKeep2=any(ismember(E1,F1(indBoundary1,:)),2); F2=element2patch(E1(logicKeep2,:)); [indBoundary2]=tesBoundary(F2); Fb=F2(indBoundary2,:); Cb=7*ones(size(Fb,1),1); for q=1:1:6 F_Cb1=Fb_bar(Cb_bar==q,:); logicNow=all(ismember(Fb,F_Cb1),2); Cb(logicNow)=q; end Cb(~any(ismember(Fb,F1(indBoundary1,:)),2))=0;

Removed unused nodes and clean up index matrices

[E,V,indFix2]=patchCleanUnused(E1(logicKeep2,:),V_bar); V(:,1)=V(:,1)-min(V(:,1)); Fb=indFix2(Fb); F=indFix2(F2); V2=V; V2(:,1)=-V2(:,1); V=[V;V2]; Fb=[Fb;fliplr(Fb)+size(V2,1)]; F=[F;fliplr(F)+size(V2,1)]; cShift=max(Cb(:))+1; Cb=[Cb;Cb+cShift]; indicesInnerSurface=unique(Fb(Cb==1,:)); logicElementsInner=any(ismember(E,indicesInnerSurface),2); E1=E; E2=E(:,[5 6 7 8 1 2 3 4]); E2=E2(~logicElementsInner,:); E=[E1;E2+size(V2,1)]; C=[ones(size(E1,1),1); 2*ones(size(E2,1),1);]; [F,V,~,ind2]=mergeVertices(F,V); Fb=ind2(Fb); E=ind2(E); indicesInnerSurface=ind2(indicesInnerSurface); actuatorLength=max(V(:,3))-min(V(:,3));

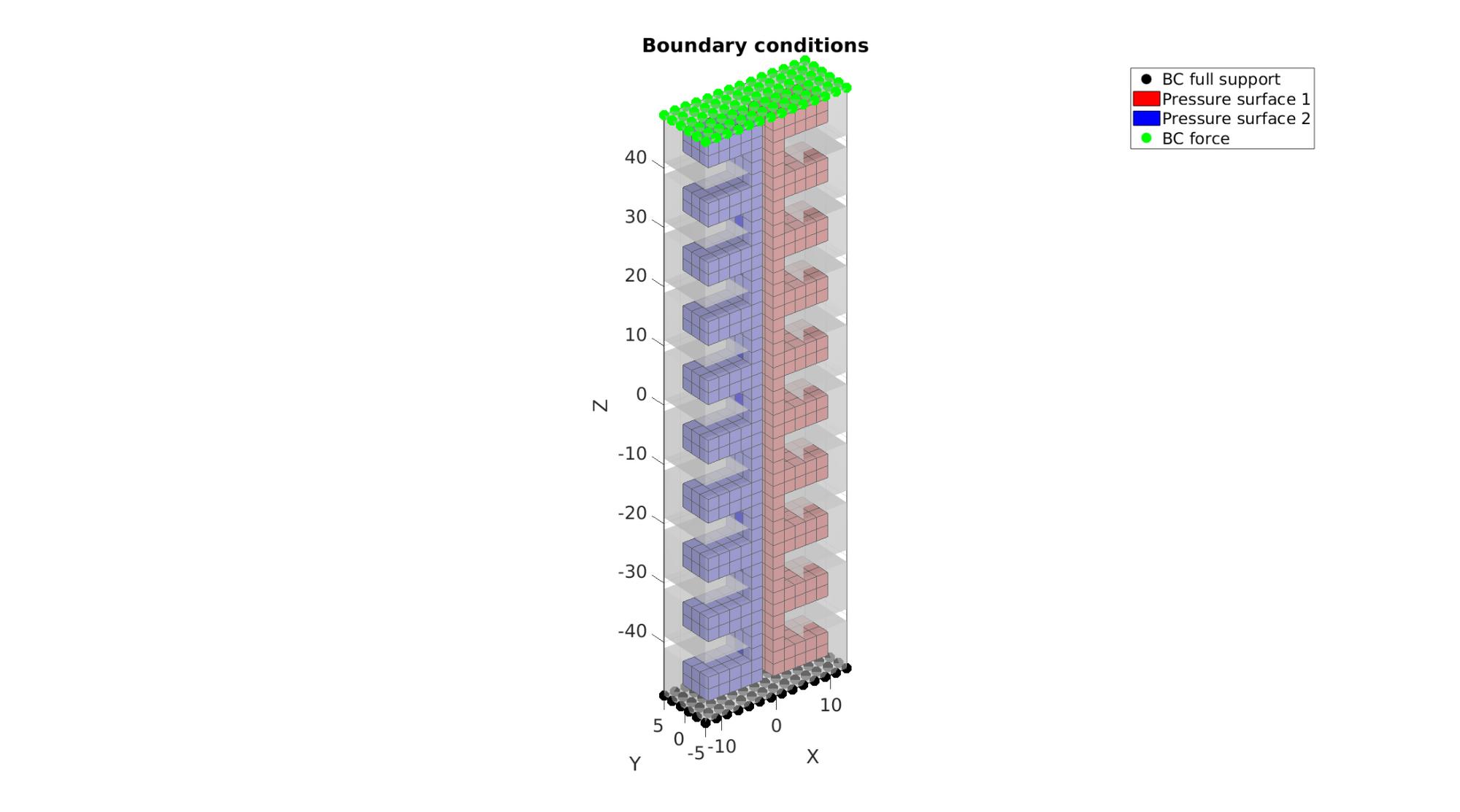

Defining the boundary conditions

The visualization of the model boundary shows colors for each side of the disc. These labels can be used to define boundary conditions.

%Define supported node sets bcSupportList=unique(Fb(ismember(Cb,[5 5+cShift]),:)); %Node set part of selected face bcPrescribeList=unique(Fb(ismember(Cb,[6 6+cShift]),:)); %Node set part of selected face %Get pressure faces F_pressure1=Fb(Cb==0,:); F_pressure2=Fb(Cb==cShift,:);

ind2=unique(E(C==2,:)); d=max(V(ind2,1)); V(ind2,1)=V(ind2,1)-d; V(:,1)=V(:,1)+d/2; % [E,V,indFix]=patchCleanUnused(E,V); % bcSupportList=indFix(bcSupportList); % bcPrescribeList=indFix(bcPrescribeList); % F_pressure1=indFix(F_pressure1); % F_pressure2=indFix(F_pressure2); [F,CF]=element2patch(E,C,'hex8'); [F,V,~,indFix]=mergeVertices(F,V); E=indFix(E); bcSupportList=indFix(bcSupportList); bcPrescribeList=indFix(bcPrescribeList); F_pressure1=indFix(F_pressure1); F_pressure2=indFix(F_pressure2); indb=tesBoundary(F); Fb=F(indb,:);

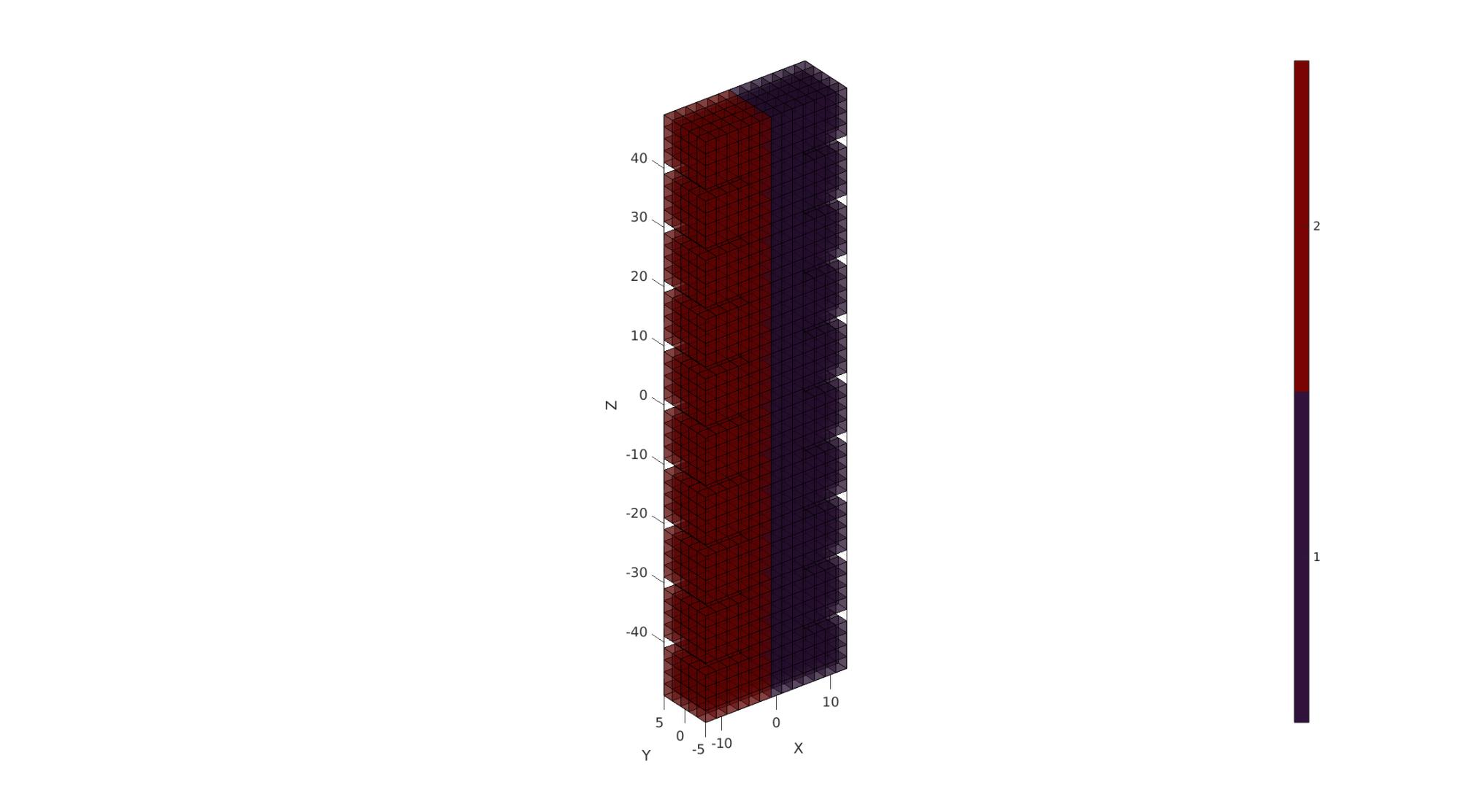

cFigure; hold on; gpatch(F,V,CF,'k',0.5); % plotV(V(indicesInnerSurface,:),'k.','MarkerSize',markerSize); axisGeom; colormap(turbo(250)); icolorbar; camlight headlight; gdrawnow;

Visualizing boundary conditions. Markers plotted on the semi-transparent model denote the nodes in the various boundary condition lists.

hf=cFigure; title('Boundary conditions','FontSize',fontSize); xlabel('X','FontSize',fontSize); ylabel('Y','FontSize',fontSize); zlabel('Z','FontSize',fontSize); hold on; gpatch(Fb,V,'w','none',0.5); hl(1)=plotV(V(bcSupportList,:),'k.','MarkerSize',markerSize); hl(2)=gpatch(F_pressure1,V,'r','k',1); hl(3)=gpatch(F_pressure2,V,'b','k',1); hl(4)=plotV(V(bcPrescribeList,:),'g.','MarkerSize',markerSize); patchNormPlot(F_pressure1,V); legend(hl,{'BC full support','Pressure surface 1','Pressure surface 2','BC force'}); axisGeom(gca,fontSize); camlight headlight; gdrawnow;

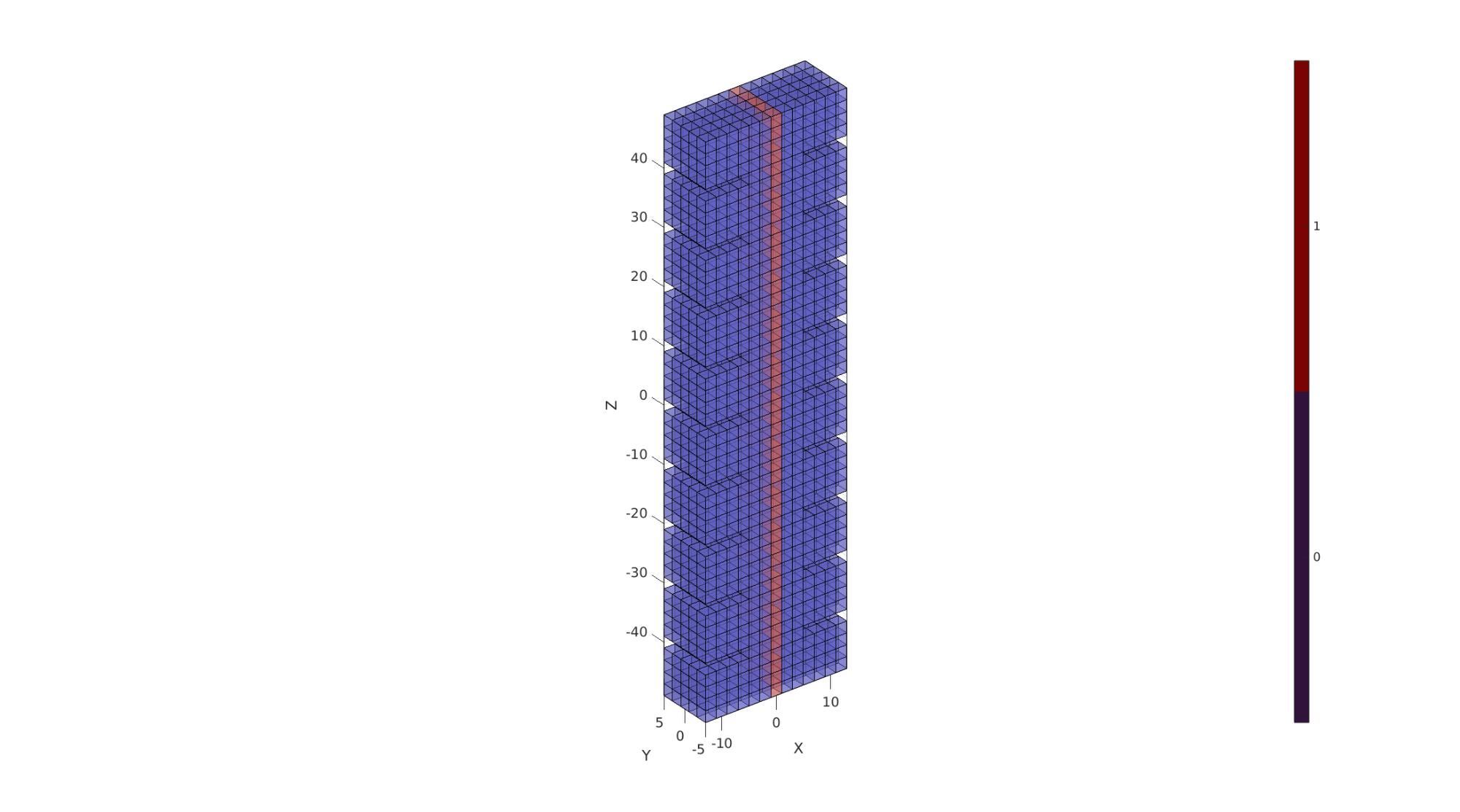

Split element regions (central plate and sides);

XE=patchCentre(E,V(:,1)); logicElementsInner=abs(XE)<eps; E1=E(~logicElementsInner,:); %Other elements E2=E(logicElementsInner,:); %Inner element layer E=[E1;E2]; [F1]=element2patch(E1); [F2]=element2patch(E2);

cFigure; hold on; gpatch(F1,V,'bw','k',0.5); gpatch(F2,V,'rw','k',0.5); axisGeom; colormap(turbo(250)); icolorbar; camlight headlight; gdrawnow;

Defining the FEBio input structure

See also febioStructTemplate and febioStruct2xml and the FEBio user manual.

%Get a template with default settings [febio_spec]=febioStructTemplate; %febio_spec version febio_spec.ATTR.version='4.0'; %Module section febio_spec.Module.ATTR.type='solid'; %Control section febio_spec.Control.analysis='STATIC'; febio_spec.Control.time_steps=numTimeSteps; febio_spec.Control.step_size=1/numTimeSteps; febio_spec.Control.solver.max_refs=max_refs; febio_spec.Control.solver.qn_method.max_ups=max_ups; febio_spec.Control.time_stepper.dtmin=dtmin; febio_spec.Control.time_stepper.dtmax=dtmax; febio_spec.Control.time_stepper.max_retries=max_retries; febio_spec.Control.time_stepper.opt_iter=opt_iter; %Material section materialName1='Material1'; febio_spec.Material.material{1}.ATTR.name=materialName1; febio_spec.Material.material{1}.ATTR.type='Ogden'; febio_spec.Material.material{1}.ATTR.id=1; febio_spec.Material.material{1}.c1=c1; febio_spec.Material.material{1}.m1=m1; febio_spec.Material.material{1}.c2=c1; febio_spec.Material.material{1}.m2=-m1; febio_spec.Material.material{1}.k=k; materialName2='Material2'; febio_spec.Material.material{2}.ATTR.name=materialName2; febio_spec.Material.material{2}.ATTR.type='Ogden'; febio_spec.Material.material{2}.ATTR.id=2; febio_spec.Material.material{2}.c1=c2; febio_spec.Material.material{2}.m1=m2; febio_spec.Material.material{2}.c2=c2; febio_spec.Material.material{2}.m2=-m2; febio_spec.Material.material{2}.k=k2; %Mesh section % -> Nodes febio_spec.Mesh.Nodes{1}.ATTR.name='nodeSet_all'; %The node set name febio_spec.Mesh.Nodes{1}.node.ATTR.id=(1:size(V,1))'; %The node id's febio_spec.Mesh.Nodes{1}.node.VAL=V; %The nodel coordinates % -> Elements partName1='Part1'; febio_spec.Mesh.Elements{1}.ATTR.name=partName1; %Name of this part febio_spec.Mesh.Elements{1}.ATTR.type='hex8'; %Element type febio_spec.Mesh.Elements{1}.elem.ATTR.id=(1:1:size(E1,1))'; %Element id's febio_spec.Mesh.Elements{1}.elem.VAL=E1; %The element matrix partName2='Part2'; febio_spec.Mesh.Elements{2}.ATTR.name=partName2; %Name of this part febio_spec.Mesh.Elements{2}.ATTR.type='hex8'; %Element type febio_spec.Mesh.Elements{2}.elem.ATTR.id=size(E1,1)+(1:1:size(E2,1))'; %Element id's febio_spec.Mesh.Elements{2}.elem.VAL=E2; %The element matrix % -> Surfaces surfaceName1='LoadedSurface1'; febio_spec.Mesh.Surface{1}.ATTR.name=surfaceName1; febio_spec.Mesh.Surface{1}.quad4.ATTR.id=(1:1:size(F_pressure1,1))'; febio_spec.Mesh.Surface{1}.quad4.VAL=F_pressure1; surfaceName2='LoadedSurface2'; febio_spec.Mesh.Surface{2}.ATTR.name=surfaceName2; febio_spec.Mesh.Surface{2}.quad4.ATTR.id=(1:1:size(F_pressure2,1))'; febio_spec.Mesh.Surface{2}.quad4.VAL=F_pressure2; % -> NodeSets nodeSetName1='bcSupportList'; febio_spec.Mesh.NodeSet{1}.ATTR.name=nodeSetName1; febio_spec.Mesh.NodeSet{1}.VAL=mrow(bcSupportList); %MeshDomains section febio_spec.MeshDomains.SolidDomain{1}.ATTR.name=partName1; febio_spec.MeshDomains.SolidDomain{1}.ATTR.mat=materialName1; febio_spec.MeshDomains.SolidDomain{2}.ATTR.name=partName2; febio_spec.MeshDomains.SolidDomain{2}.ATTR.mat=materialName2; %Boundary condition section % -> Fix boundary conditions febio_spec.Boundary.bc{1}.ATTR.name='zero_displacement_xyz'; febio_spec.Boundary.bc{1}.ATTR.type='zero displacement'; febio_spec.Boundary.bc{1}.ATTR.node_set=nodeSetName1; febio_spec.Boundary.bc{1}.x_dof=1; febio_spec.Boundary.bc{1}.y_dof=1; febio_spec.Boundary.bc{1}.z_dof=1; %Loads section % -> Surface load febio_spec.Loads.surface_load{1}.ATTR.type='pressure'; febio_spec.Loads.surface_load{1}.ATTR.surface=surfaceName1; febio_spec.Loads.surface_load{1}.pressure.ATTR.lc=1; febio_spec.Loads.surface_load{1}.pressure.VAL=appliedPressure1; febio_spec.Loads.surface_load{1}.symmetric_stiffness=1; febio_spec.Loads.surface_load{2}.ATTR.type='pressure'; febio_spec.Loads.surface_load{2}.ATTR.surface=surfaceName2; febio_spec.Loads.surface_load{2}.pressure.ATTR.lc=1; febio_spec.Loads.surface_load{2}.pressure.VAL=appliedPressure2; febio_spec.Loads.surface_load{2}.symmetric_stiffness=1; %LoadData section % -> load_controller febio_spec.LoadData.load_controller{1}.ATTR.id=1; febio_spec.LoadData.load_controller{1}.ATTR.type='loadcurve'; febio_spec.LoadData.load_controller{1}.interpolate='LINEAR'; febio_spec.LoadData.load_controller{1}.points.point.VAL=[0 0; 1 1]; %Output section % -> log file febio_spec.Output.logfile.ATTR.file=febioLogFileName; febio_spec.Output.logfile.node_data{1}.ATTR.file=febioLogFileName_disp; febio_spec.Output.logfile.node_data{1}.ATTR.data='ux;uy;uz'; febio_spec.Output.logfile.node_data{1}.ATTR.delim=','; febio_spec.Output.logfile.node_data{1}.VAL=1:size(V,1); febio_spec.Output.logfile.element_data{1}.ATTR.file=febioLogFileName_stress; febio_spec.Output.logfile.element_data{1}.ATTR.data='s1'; febio_spec.Output.logfile.element_data{1}.ATTR.delim=','; febio_spec.Output.logfile.element_data{1}.VAL=1:size(E,1); % Plotfile section febio_spec.Output.plotfile.compression=0;

Quick viewing of the FEBio input file structure

The febView function can be used to view the xml structure in a MATLAB figure window.

febView(febio_spec); %Viewing the febio file

Exporting the FEBio input file

Exporting the febio_spec structure to an FEBio input file is done using the febioStruct2xml function.

febioStruct2xml(febio_spec,febioFebFileName); %Exporting to file and domNode % febView(febioFebFileName);

Running the FEBio analysis

To run the analysis defined by the created FEBio input file the runMonitorFEBio function is used. The input for this function is a structure defining job settings e.g. the FEBio input file name. The optional output runFlag informs the user if the analysis was run succesfully.

febioAnalysis.run_filename=febioFebFileName; %The input file name febioAnalysis.run_logname=febioLogFileName; %The name for the log file febioAnalysis.disp_on=1; %Display information on the command window febioAnalysis.runMode=runMode; [runFlag]=runMonitorFEBio(febioAnalysis);%START FEBio NOW!!!!!!!!

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

--------> RUNNING/MONITORING FEBIO JOB <-------- 01-May-2023 09:17:50

FEBio path: /home/kevin/FEBioStudio/bin/febio4

# Attempt removal of existing log files 01-May-2023 09:17:50

* Removal succesful 01-May-2023 09:17:50

# Attempt removal of existing .xplt files 01-May-2023 09:17:51

* Removal succesful 01-May-2023 09:17:51

# Starting FEBio... 01-May-2023 09:17:51

Max. total analysis time is: Inf s

* Waiting for log file creation 01-May-2023 09:17:51

Max. wait time: 30 s

* Log file found. 01-May-2023 09:17:51

# Parsing log file... 01-May-2023 09:17:51

number of iterations : 12 01-May-2023 09:17:52

number of reformations : 12 01-May-2023 09:17:52

------- converged at time : 0.1 01-May-2023 09:17:52

number of iterations : 12 01-May-2023 09:17:53

number of reformations : 12 01-May-2023 09:17:53

------- converged at time : 0.2 01-May-2023 09:17:53

number of iterations : 12 01-May-2023 09:17:53

number of reformations : 12 01-May-2023 09:17:53

------- converged at time : 0.3 01-May-2023 09:17:53

number of iterations : 12 01-May-2023 09:17:54

number of reformations : 12 01-May-2023 09:17:54

------- converged at time : 0.4 01-May-2023 09:17:54

number of iterations : 12 01-May-2023 09:17:55

number of reformations : 12 01-May-2023 09:17:55

------- converged at time : 0.5 01-May-2023 09:17:55

number of iterations : 12 01-May-2023 09:17:56

number of reformations : 12 01-May-2023 09:17:56

------- converged at time : 0.6 01-May-2023 09:17:56

number of iterations : 12 01-May-2023 09:17:56

number of reformations : 12 01-May-2023 09:17:56

------- converged at time : 0.7 01-May-2023 09:17:56

number of iterations : 12 01-May-2023 09:17:57

number of reformations : 12 01-May-2023 09:17:57

------- converged at time : 0.8 01-May-2023 09:17:57

number of iterations : 12 01-May-2023 09:17:58

number of reformations : 12 01-May-2023 09:17:58

------- converged at time : 0.9 01-May-2023 09:17:58

number of iterations : 10 01-May-2023 09:17:58

number of reformations : 10 01-May-2023 09:17:58

------- converged at time : 1 01-May-2023 09:17:58

Elapsed time : 0:00:07 01-May-2023 09:17:58

N O R M A L T E R M I N A T I O N

# Done 01-May-2023 09:17:58

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

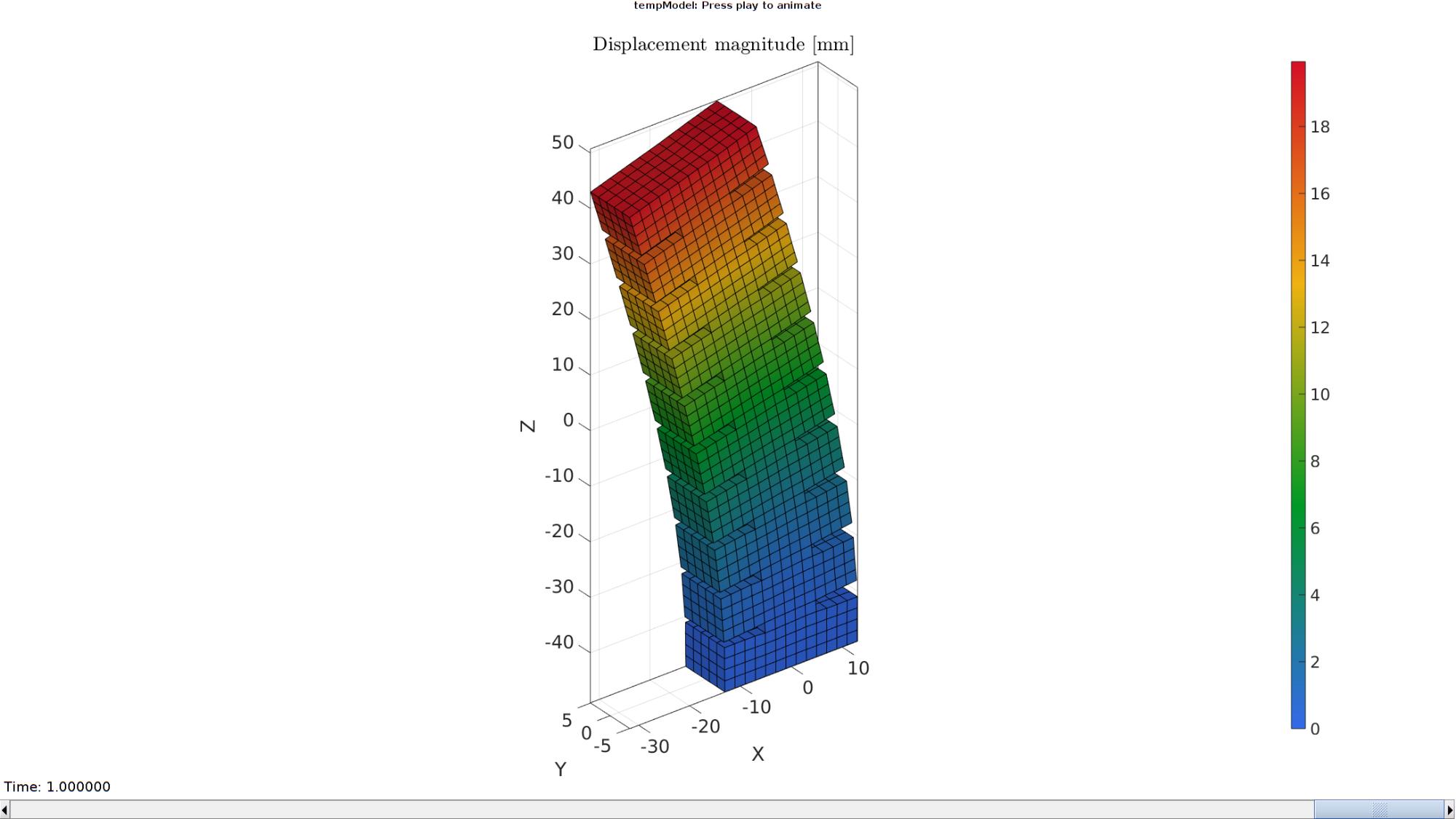

Import FEBio results

if runFlag==1 %i.e. a succesful run

Importing nodal displacements from a log file

dataStruct=importFEBio_logfile(fullfile(savePath,febioLogFileName_disp),0,1);

%Access data

N_disp_mat=dataStruct.data; %Displacement

timeVec=dataStruct.time; %Time

%Create deformed coordinate set

V_DEF=N_disp_mat+repmat(V,[1 1 size(N_disp_mat,3)]);

Plotting the simulated results using anim8 to visualize and animate deformations

DN_magnitude=sqrt(sum(N_disp_mat(:,:,end).^2,2)); %Current displacement magnitude % Create basic view and store graphics handle to initiate animation hf=cFigure; %Open figure gtitle([febioFebFileNamePart,': Press play to animate']); title('Displacement magnitude [mm]','Interpreter','Latex') hp=gpatch(Fb,V_DEF(:,:,end),DN_magnitude,'k',1); %Add graphics object to animate % hp.Marker='.'; % hp.MarkerSize=markerSize2; hp.FaceColor='interp'; axisGeom(gca,fontSize); colormap(gjet(250)); colorbar; caxis([0 max(DN_magnitude)]); axis(axisLim(V_DEF)); %Set axis limits statically camlight headlight; % Set up animation features animStruct.Time=timeVec; %The time vector for qt=1:1:size(N_disp_mat,3) %Loop over time increments DN_magnitude=sqrt(sum(N_disp_mat(:,:,qt).^2,2)); %Current displacement magnitude %Set entries in animation structure animStruct.Handles{qt}=[hp hp]; %Handles of objects to animate animStruct.Props{qt}={'Vertices','CData'}; %Properties of objects to animate animStruct.Set{qt}={V_DEF(:,:,qt),DN_magnitude}; %Property values for to set in order to animate end anim8(hf,animStruct); %Initiate animation feature drawnow;

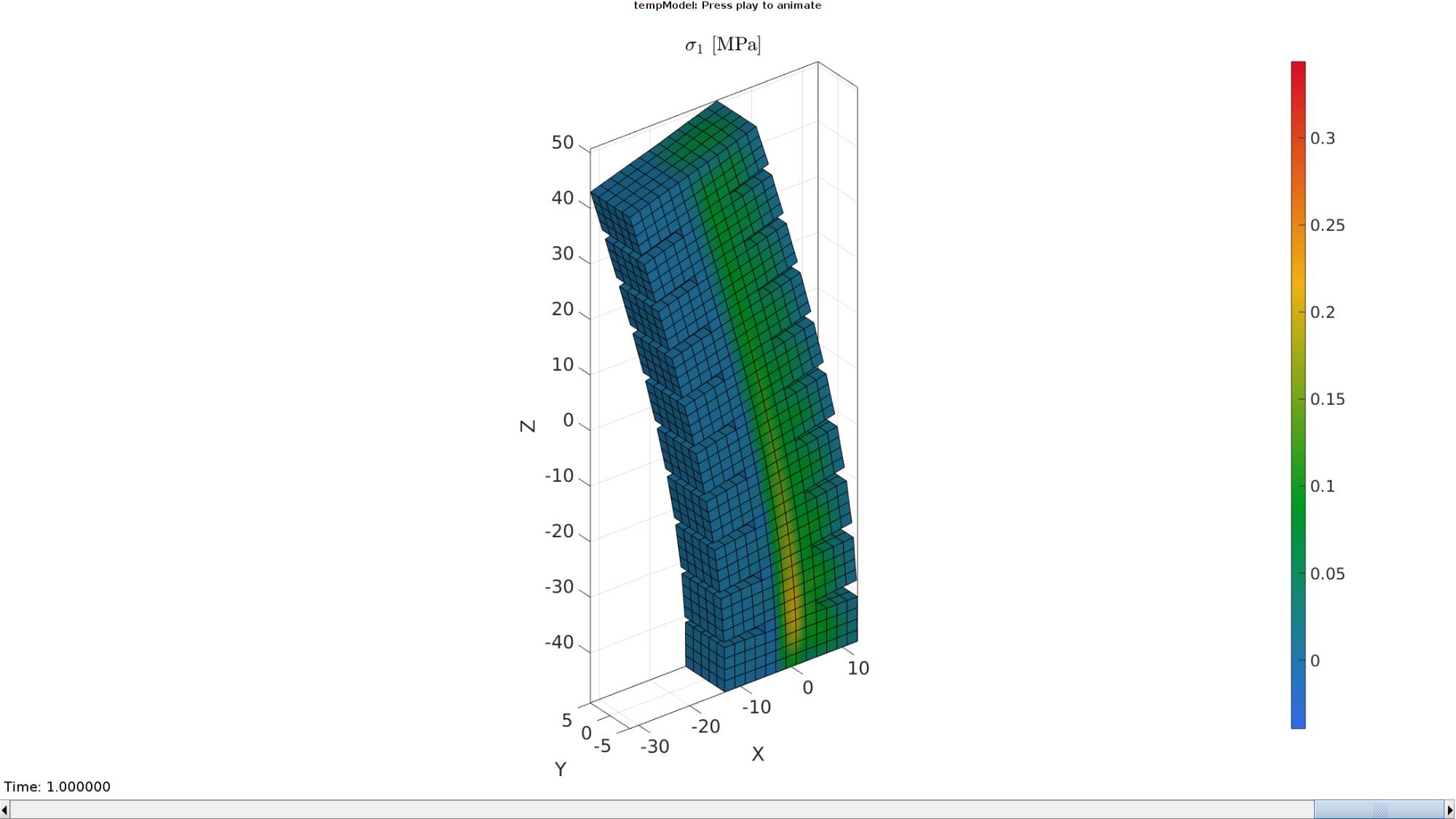

Importing element stress from a log file

dataStruct=importFEBio_logfile(fullfile(savePath,febioLogFileName_stress),0,1);

%Access data

E_stress_mat=dataStruct.data;

E_stress_mat(isnan(E_stress_mat))=0;

Plotting the simulated results using anim8 to visualize and animate deformations

[CV]=faceToVertexMeasure(E,V,E_stress_mat(:,:,end));

% Create basic view and store graphics handle to initiate animation

hf=cFigure; %Open figure

gtitle([febioFebFileNamePart,': Press play to animate']);

title('$\sigma_{1}$ [MPa]','Interpreter','Latex')

hp=gpatch(Fb,V_DEF(:,:,end),CV,'k',1); %Add graphics object to animate

% hp.Marker='.';

% hp.MarkerSize=markerSize2;

hp.FaceColor='interp';

axisGeom(gca,fontSize);

colormap(gjet(250)); colorbar;

caxis([min(E_stress_mat(:)) max(E_stress_mat(:))]);

axis(axisLim(V_DEF)); %Set axis limits statically

camlight headlight;

% Set up animation features

animStruct.Time=timeVec; %The time vector

for qt=1:1:size(N_disp_mat,3) %Loop over time increments

[CV]=faceToVertexMeasure(E,V,E_stress_mat(:,:,qt));

%Set entries in animation structure

animStruct.Handles{qt}=[hp hp]; %Handles of objects to animate

animStruct.Props{qt}={'Vertices','CData'}; %Properties of objects to animate

animStruct.Set{qt}={V_DEF(:,:,qt),CV}; %Property values for to set in order to animate

end

anim8(hf,animStruct); %Initiate animation feature

drawnow;

end

GIBBON www.gibboncode.org

Kevin Mattheus Moerman, [email protected]

GIBBON footer text

License: https://github.com/gibbonCode/GIBBON/blob/master/LICENSE

GIBBON: The Geometry and Image-based Bioengineering add-On. A toolbox for image segmentation, image-based modeling, meshing, and finite element analysis.

Copyright (C) 2006-2022 Kevin Mattheus Moerman and the GIBBON contributors

This program is free software: you can redistribute it and/or modify it under the terms of the GNU General Public License as published by the Free Software Foundation, either version 3 of the License, or (at your option) any later version.

This program is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; without even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU General Public License for more details.

You should have received a copy of the GNU General Public License along with this program. If not, see http://www.gnu.org/licenses/.